TECHNI Waterjet

TechniWaterjet™ is your trusted partner when it comes to giving your business a competitive advantage using the finest waterjet cutting method. Our team of engineers has been developing and innovating new complete high-pressure water jet cutting solutions for over 30 years. We pride ourselves on working closely with your business to identify your challenges and provide you with the ultimate water jet cutting machine for your application. Our highly trained team will offer you the support and machinery you need to ensure your success in generating a high return on your investment.

BENEFITS OF OUR PRODUCTS

Our high-quality product portfolio offers diverse advantages which aim to make the use of our products easy for operators as well as cost-efficient due to a high life-expectancy of machine and parts and less resource consumption.

ADVANTAGES FOR CUTTING ROUTINE AND PRODUCTION

Special piercing routine, software controlled

Easy setting of piercing routine

Automatic adjustment of offset, according to real mixing tube wear

Special program for cutting glass

Possibility to operate at low pressure of down to 200 bar

Sensors at machine allow an operation of machine without constant personnel presence

Intensive training and support for your production

ADVANTAGES FOR PUMP:

Smaller, quieter and more efficient than intensifier pump

High cost-efficiency up to 60% compared to hydraulic-driven pumps through significantly lower energy consumption

75% Less cooling water needed

Pump motor only running when cutting head is open

Minimized Dead-Head peaks <5%

Constant pressure

Longer life expectancy of HD pipes and fittings

Less abrasive needed, automated management of abrasive supply

Smoother edges

Easy operation

Advanced Diagnostic Kit allows predictive maintenance and therefore prevents standstills

Easy pump maintenance

Remote pump diagnostic and control possible

Lower electrical fuse ampere needed; 60 Amp with Techni servo pump compared to 80-125 with hydraulic-driven pump

No oil needed in servo pump therefore no risk of oil contaminating cutting water and tank water

ADVANTAGES FOR WATER TREATMENT AND ENVIRONMENT

Reduction of needed water resources through effective and efficient water treatment system to recycle cutting water and increasing waste water quality

Increase of life expectancy of machines and components through an increased cutting water quality through our water treatment system WodaCodeGreen

Increase of Warranty period through an increased life expectancy when using our water treatment system WodaCodeGreen

Reduction of needed personnel and time resource during water tank desludging through abrasive desludging system WodaGarnetClean

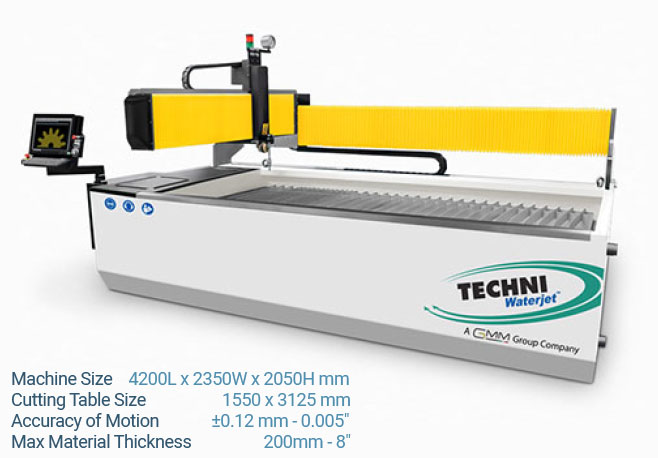

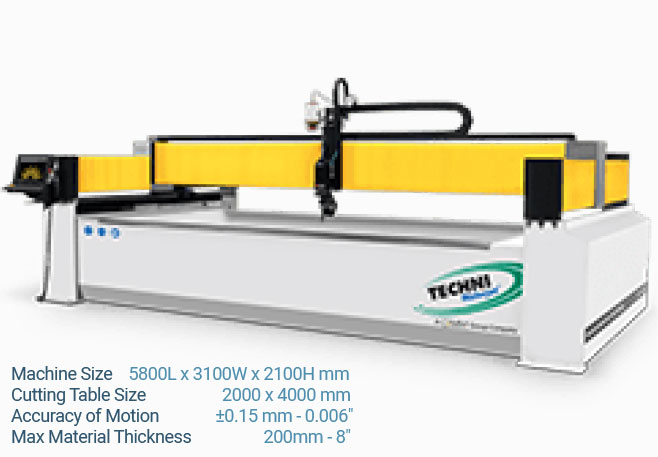

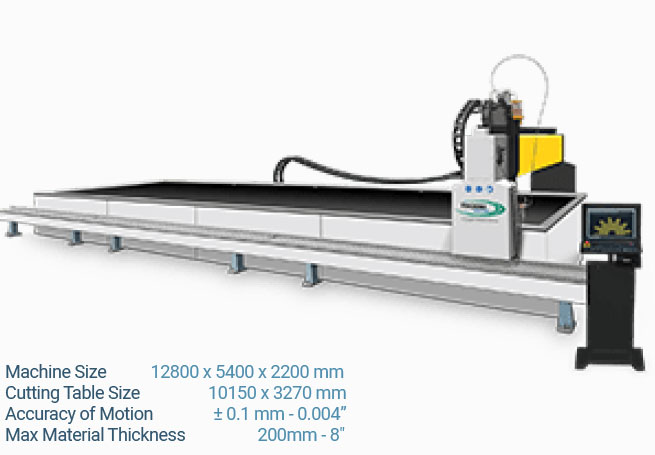

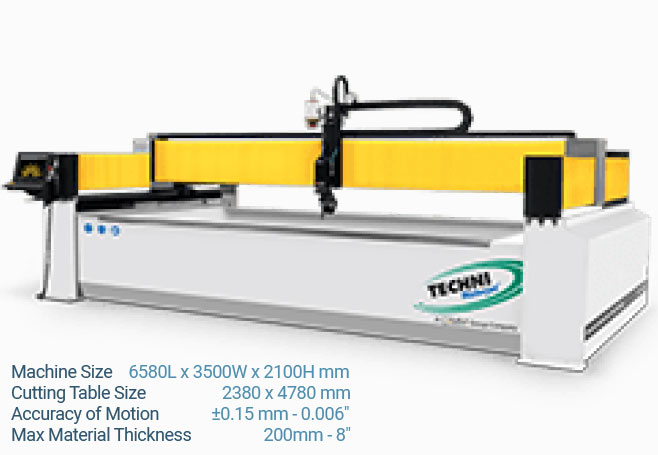

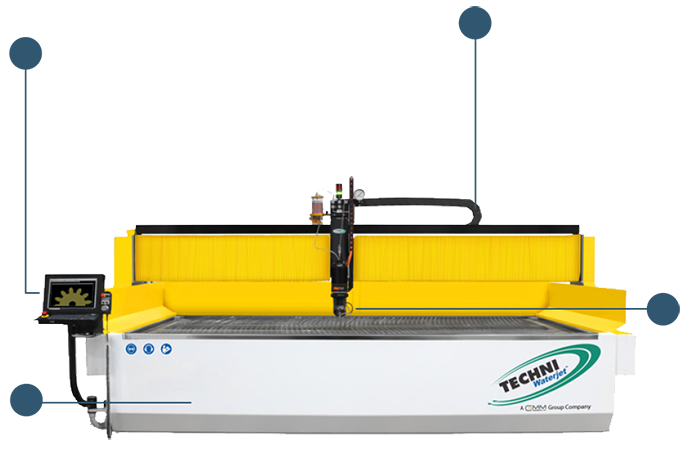

Why use the Intec™G2 Series CNC Waterjet Machine

Simple to use means no special skills required to produce accurate parts in any material

Superior edge quality means more time saved on secondary finishing

Versatile cutting allows you to cut multiple material types on the same bed without having to change tooling Cutting

Abrasive Hopper

The abrasive hopper and flow control system, accurately measures and dispenses the right amount of abrasive required at the nozzle to

Complete the cutting process

Control Software Monitor

Our advanced motion control system is PC based and the entire machine can be managed from this monitor, which is easy to use with some simple training.

Abrasive Waterjet Nozzle

Inside the nozzle the pressurized water passes trough a small diameter orifice and forms a coherent jet of water. The mixture of water and abrasive passes through a special mixing tube to form the slurry that exits at very high speeds which causes the cutting process to begin.

Cutting Bed / Catcher Tank

The G2 series machines are built with different cutting table sizes, starting from 936/1,576 mm to 3,200/10,000 mm, so that you can easily cut small and large pieces to dissipate the high-pressure water from the jet and to reduce the noise.

היכרות עם סדרת Intec™G2 Abrasive Waterjet

היכרות עם סדרת Intec™G2 Abrasive Waterjet