Abrasive removal system WodaGarnetClean

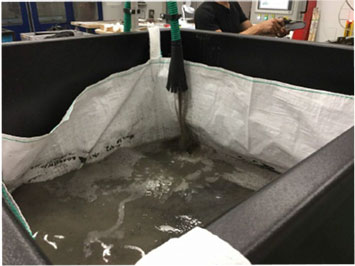

During water jet production, the sludge (sand/abrasive) is deposited in the cutting basin, so that it very often requires extensive cleaning. In addition, the water is contaminated with harmful substances – but legal standards prescribe what may be discharged into the sewerage system. With the products of our Woda-series we support you to meet legal and ecological requirements on the one hand and to save working time for cleaning the collecting basins on the other hand.

- Without electricity (only compressed air)

- Mobile, flexible and applicable for every machine type

- incl. 3 filter fabric bags (1t each)

- Full control through user-friendly, manual control

With the mobile manual system for manual removal of abrasive agent WodaGarnetClean you can remove abrasive sludge from any waterjet cutting system quickly and easily. The complete desludging system requires only compressed air (2-6 bar) and can be used variably where it is needed.

With the help of the suction lance, water is pumped into the deposited sand to stir up the hardened mass. The water-sand mixture is then sucked in and pumped into the collecting tank. Sand and coarse suspended particles are deposited in the suspended filter fabric bag (can be ordered from the dealer). The water can be pumped back into the water tank and the filled fabric bag can be removed with a forklift truck.

With WodaGarnetClean between 3 and 4 m³ of water per hour can be pumped and thus up to 1t of abrasive per hour can be filtered out. A container with e.g. 4x2m can be cleaned in about 3h.

Advantages of using the WodaGarnetClean system:

Save on time and man-power

by eliminating the lengthy and manual process of cleaning the waterjet tank

Built to Last

the Abrasive Removal System’s heavy-duty design is mounted on a steel frame to ensure a long life span

Reduce Water Usage

by having the removal system clean and separate the abrasive from the water after cutting, so that the water can be recycled

Save Time On Secondary Finishing

within this unit gives your workshop an extra layer of safety when operating your Waterjet machine

Cutting water treatment WodaCodeGreen

Untreated cutting water considerably reduces the service life of your waterjet cutting machine. There is hardly any other application in water hydraulics where water is exposed to such high mechanical loads as in waterjet cutting. At a pressure of over 4000 bar and large flow rates at high speed, deficiencies in water quality become directly noticeable by a shortened service life of critical parts. From damaged seals and nozzles, damaged valves and cylinders to deposits on control valves and burst pipes. Therefore, due to the high demands of waterjet cutting, it is particularly important to have the best possible cutting water quality.

:Advantages of using the WodaCodeGreen system

- Cost saving: Maintenance intervals of the high-pressure pump are extended by 50 – 500% for short downtime

- Operational safety: Water-related faults or damage to the high-pressure pump are considerably reduced

- Fast amortization with moderate consumption costs for replacement filters and dosing additives

- Low service costs: trouble-free and low-maintenance technical and electronic construction

Filtration and oxidation

The combination of filters and filter materials not only removes solids down to 1 μm like conventional filters. WodaCode also removes chlorine, which is often used to disinfect pipelines and gradually destroys seals. In addition, it changes and removes dissolved iron and other metals or corrosion products from the lines, which otherwise leads to ever-increasing layers that destroy check valves and seals.

Softening and degassing

The catalytic granulate forces the carbon dioxide dissolved in the water to outgas, whereby the hardness remains firmly bound in calcite clusters. This process has two advantages: It reduces the content of carbonic acid, which damages the high-pressure systems by cavitation, and it binds calcium carbonate, which would otherwise lead to lime deposits on cylinders and valves.

Comparison of consumption costs

Compared to conventional systems, WodaCodeGreen can save up to 80% of the running costs for water treatment. With an 8-hour shift and a 5-day week for a cutting machine with a water consumption of Q = 5 l/min, the total water consumption is 600 m³ per year.

Did you already know:

Many manufacturers grant repairs and the replacement of wearing parts under warranty only if it can be proven that the water used meets the relevant technical specifications.

Technical data WodaCodeGreen

WodaCodeGreen produces crystal clear, softened water for your machines - without using expensive and harmful chemicals.

The system works efficiently and virtually trouble-free thanks to the absence of susceptible electronic controls. The system is very easy to handle with its cartridge system and is quickly set up for your operation by means of plug-and-play installation.

WodeCodeGreen filters:

- All solids down to 1µm

- All corrosion products

- All heavy metals

- Total, carbonate and sulphate hardness

- Organic compounds (phenols, pesticides, solvents, thinners, oils and alcohols)

- Removes silicon dioxide

- Chlorine, free carbonic acid and oxygen

- All microorganisms including bacteria, algae and fungi

Technical specifications:

- Permissible water inlet pressure: max. 10 bar

- Setting pressure reducer: max. 5.5 bar

- Water inlet temperature: 10 to 35°C

- Maximum flow rate Qmax: 16 liters/min

- Conductivity in water input: 200 – 1200 µS/cm

- TDS in water inlet: 140 to 840 ppm

- Filtration: activated carbon filter 10µm (inlet), police filter 1µm (outlet)

- Recommended change rhythm (activated carbon filter): heavily contaminated and/or pressure loss Δp >0.4 bar

- Recommended change rhythm (oxi and granulate fine filter): at the latest after 3 months or 200m³ water flow

- Approx. dimensions Width x Depth x Height in cm: 66x 60x 165

- Connections Input/Output: 3/4″ thread or hose nozzle

- Weight: 185 kg

Waste Water Filtration WodaSettlingTank

WodaSettlingTank: separation of suspended solids and wastewater

With the help of the Woda Settling Tank, suspended matter (sand, abrasion) can be separated from the water before it gets into the drain. Due to the special guidance and flow of the water in the 3-stage tanks, the substances settle in the steel tanks.

- Works without electricity

- 3 powder-coated steel basins

- Washable filters

- Special water flow for sedimentation of suspended solids (abrasives, sand)

- Low maintenance and trouble-free operation