call now 03-5224440

Ecojet uses the most advanced equipment in the industry and we have a Intec-G2® Water Jet Cutting Machine

The Intec-G2® waterjet machine will bring tremendous benefits and expanded capabilities to your operation. Below we have listed some of the many possibilities that are available to you through the use of our waterjet machines.

PAC 60™ 5-Axis Head

Produce Parts with a True Angel Up to +/- 60 Degrees

The PAC 60™ is capable of producing parts with a true angle up to +/- 60 degrees, with continuous rotation. That means, regardless of the geometry of the part to be cut, the PAC 60™ will produce accurate parts without having to reposition the cutting head, saving time and producing higher quality parts.

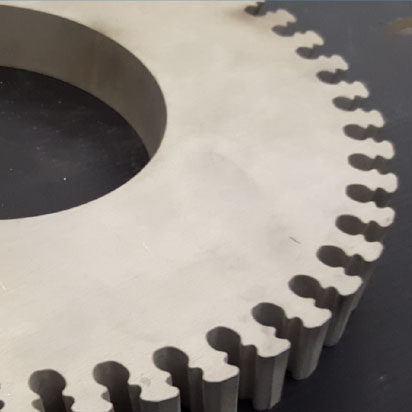

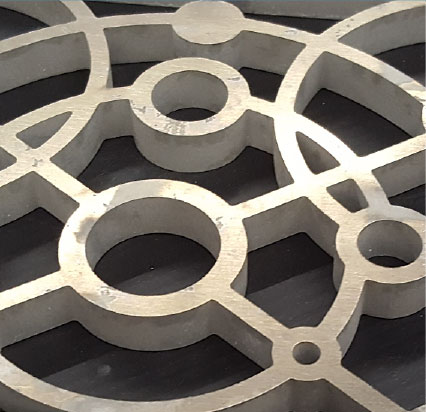

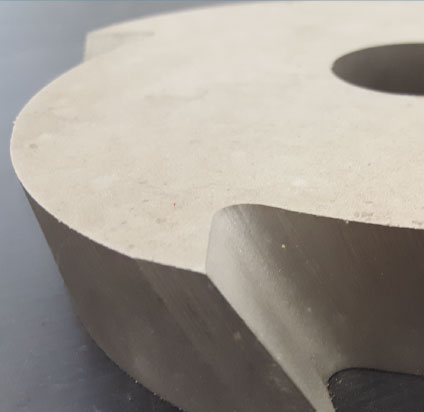

We use two different water jet cutting methods: Pure water and abrasive cutting. In both processes we can cut materials up to 200 mm in thickness. For very small and precise parts, such as for medical or automotive applications, we use Microjet technology with a cutting width of only 0.25 mm.

We use pure water cutting to cut soft materials such as foam, rubber, wood and many others. If a hard material, such as glass, bullet-proof glass, plastic, metals (steel, tool steel, copper, titanium, aluminium, etc.), stones, ceramics, composite materials (GRP, CFRP), etc. is to be cut, we use the abrasive method.