Waterjet Accessories

Equip your waterjet machine with attachments that enhance your cutting capabilities

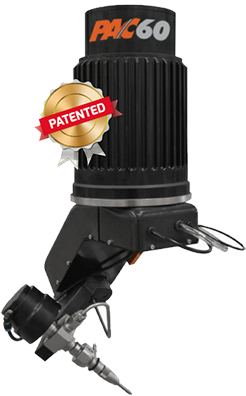

PAC 60 5-Axis Head

PAC 60 5-Axis Head

Produce Parts with a True Angel Up to +/- 60 Degrees

The PAC 60 is capable of producing parts with a true angle up to +/- 60 degrees, with continuous rotation. That means, regardless of the geometry of the part to be cut, the PAC 60 will produce accurate parts without having to reposition the cutting head, saving time and producing higher quality parts.

Advantages of using PAC60™ technology

- Manufacture Higher Quality Parts in any material direct from your machine bed

- Save Time on Secondary Finishing with in built taper compensation

- Accelerate the Cutting Process by producing complex geometries without having to reposition the cutting head

- Produce More Complex Parts with true angles of up to +/- 60 degrees

Twice the Power Twice the Speedmultiple cutting heads

The option of multiple cutting heads gives the Techni Waterjet™ Cutting Machine the power and speed to provide the highest level of productivity, in the most demanding production environments.

Option 1 is mounted on an aluminum spreader bar, the cutting heads can be quickly and easily positioned whilst still featuring the unique breakaway head configuration. This feature allows the machine to automatically shut down one of the cutting heads if either one of them comes into contact with a foreign object such a fixing clamp.

Option 2 is Independently mounted cutting heads, which allows for an accurate stand-off to be set and maintained on each cutting head.

- Double Machine Productivity and output by utilizing the power of multiple, highly accurate cutting heads

- By Producing More Cuts Per Minute, you shorten the length it takes to make a return on your investment

- Extremely Safe to Operate the cutting heads are paired with unique breakaway head configuration sensor technology

- Have Parts Produced in Half the Time giving your workshop quicker turn around capabilities

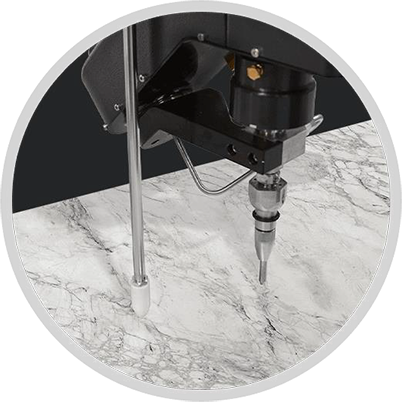

Maintain Optimal HeightWith The Skip & Float

Sheet materials are often subject to warping. The Skip and Float feature will ensure the cutting head is maintained at the optimal stand-off height above the material being cut (via the float mechanism). Without this feature, warped material can cause the cutting head to hit the material and break the focusing tube, or to partially block and not cut through the material.

The skip function automatically raises the cutting head well above the material when traversing between cuts. This ensures that the cutting head cannot catch on a cut part which may have tilted and risen above the materials. This will ensure that the focusing tube isn’t broken and the workpiece isn’t moved or damaged.

- BENEFITS OF THE Skip & Float Attachment

- Greater Versatility when cutting by allowing machines to accept warped material

- Heavily Reduced the Risk of the machine crashing on warped materials

- Ensured Efficient Cutting due to constant stand-off

- Higher Quality Parts produced due to constant stand-off

- Clamping Reduced with no need to pull the material flat

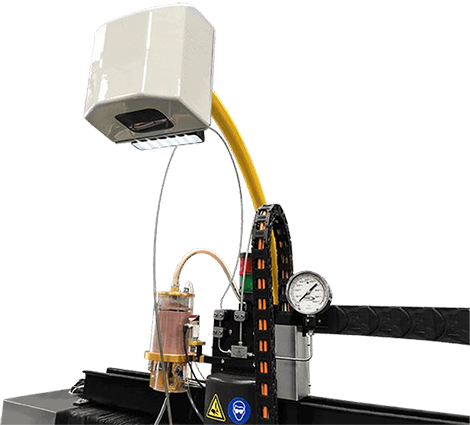

EXPERIENCE SUPER ACCURATE CUTS WITHTerrain Mapping

Touch - Probe

The Touch - Probe Height Detection option performs reliable and accurate terrain mapping on the material surface, allowing the cutting head to automatically adjust its distance before piercing and during the cutting process. By touching the surface of the plate, differences in thickness can be detected and the Z-height compensated. This is especially important to avoid unexpected results when beveling.

Laser

The optional laser sensor performs precise terrain mapping on the surface of the material to be cut. This information is then used to maintain a precise distance between the nozzle and the workpiece, resulting in more accurate parts than any other cutting head on the market. Other cutting heads only set their distance at the piercing point and then assume that the workpiece is completely flat along the cutting path, which is almost never the case. As the flatness of the material and the distance vary, the geometry of the part to be cut also changes. Constant, accurate spacing is critical in angle cutting, and the greater the angle, the more critical it becomes.

Fitting panels It has never been so easy until now

Tech – Vision

Tech – Vision is a highly sophisticated camera mounted above the machine bed that captures a bird’s eye view of the material being cut.

This allows the operator to effectively perform book edges, waterfall edges and match patterns in materials such as stone to ensure the final product is exactly what the customer wants.

In addition, the Tech Vision camera’s eye makes it much easier for the operator to ensure that the tabletop is positioned correctly before starting to cut. This avoids waste that would result from inaccurate plate alignment.

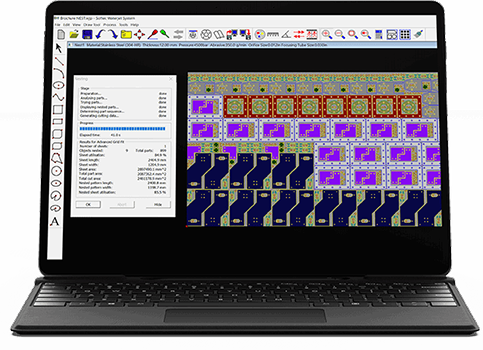

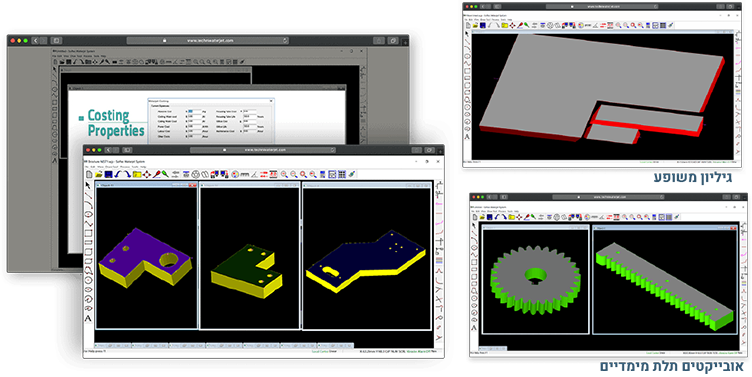

Software that makes Cutting EasyFantastic results Only with Softec

Developed By TECHNI Waterjet

Our Waterjet cutting technology was developed by our team of engineers with two very clear goals in mind. The first was to give workshops the intelligence to cut parts at a minimum cost. The second was to be able to have users control it from an all in one interface. In developing this software, we wanted to ensure the software’s ease of use. From novice to advanced levels, you can easily gain the most out of your Waterjet cut machine with Softec software.

Developed By TECHNI Waterjet < Simple To Use < Powerful & Fast < All In One Windows Solution

Bring your ideas to life In 3 simple steps

Step 1: Select material

Select your CAD file and the material you want to cut. The software then automatically loads the predefined settings for cutting that particular type of material

Step 2: Entering the dimensions

Enter the values for the material thickness, length and width of the sheet to be cut

Step 3: Confirm configuration

Confirm the configuration of your machine and press "Go", your waterjet machine will do the rest

Super Powerful Features

- DXF

- FIVE EDGE QUALITIES

- AUTO & ARRAY NESTING

- MULTIPLE PIERCING OPTIONS

- CAD PACKAGE

- COSTING & ESTIMATING PACKAGE

- REAL TIME RUNNING SIMULATION

- TROUBLE SHOOTING DIAGNOSTICS

- STANDARD OBJECTS LIBRARY

- MAINTENANCE TIMERS

NESTING SOFTWARE DESIGNED FOR The IntecG2 Series

Softec Nest™ utilises advanced nesting algorithms which have been developed by one of the world’s largest and most awarded CAD and nesting software developers.

Our nesting software makes it easy for you to maximise your waterjets performance by increasing the number of parts you can cut from one sheet of material.

- Minimises Material Waste

- Increase More Parts Per Sheet

- Minimise Rapid Feed Time

- Increase Workshop Productivity

- Increase Nesting Speed

- Increase Remnant Size