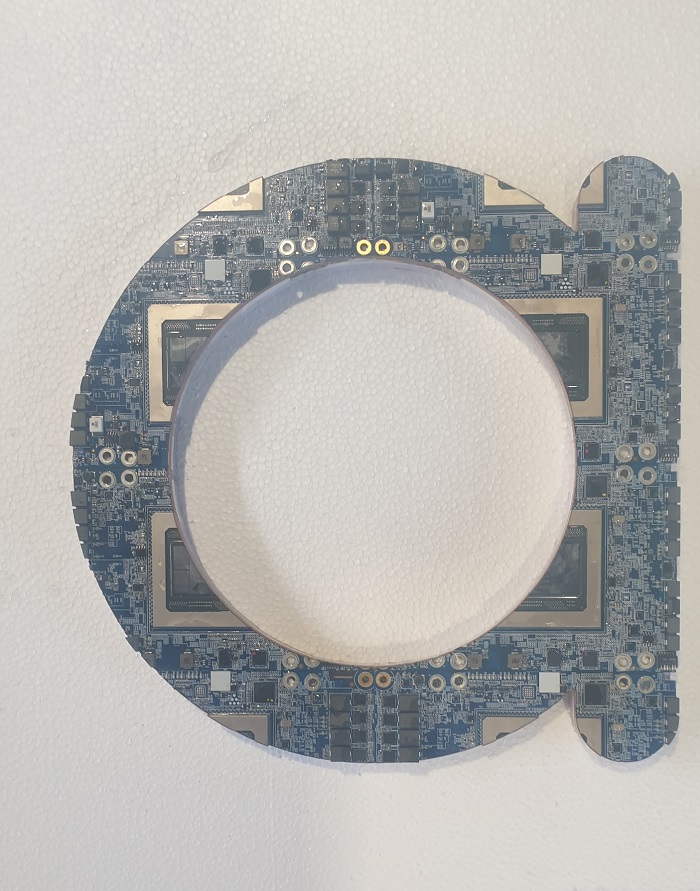

Waterjet cutting is a highly versatile cutting technology suitable for a wide range of projects. The technology is based on cutting by means of a thin stream of water that penetrates the material quickly and with high pressure, in order to perform a quick process of “erosion” at a specific point, resulting in full material cutting. A water stream, less than one millimeter in diameter, can even cut 150 mm thick hard rock as well as paper-thin and delicate glass. In practice, with waterjet cutting any raw material can be cut into complex shapes with maximum accuracy. Thin materials are usually cut only using a water stream (pure waterjet) while thick materials use a water stream with an abrasive, a type of sand combined with quartz (abrasive waterjet).